At Jumac, we focus on maximising the bottom line value and spinning performance for our customers worldwide. For this, a series of high-utility pre-sales services are offered, to help you arrive at the right purchase decisions.

After all, when it comes to sliver handling, nothing can be left to chance.

For optimising operational efficiency and maximising mill productivity levels, selecting the correct number of spinning cans and deploying them in the best possible manner is of paramount importance. It all boils down to understanding the precise sliver handling requirements at your mills, and acquiring Spinning Cans accordingly.

With our specially designed and calibrated can calculator, you can get an accurate estimate of the number of cans you need to order. Get started here.

For optimising operational efficiency and maximising mill productivity levels, selecting the correct number of spinning cans and deploying them in the best possible manner is of paramount importance. It all boils down to understanding the precise sliver handling requirements at your mills, and acquiring Spinning Cans accordingly.

With our specially designed and calibrated can calculator, you can get an accurate estimate of the number of cans you need to order. Get started here.

For optimising operational efficiency and maximising mill productivity levels, selecting the correct number of spinning cans and deploying them in the best possible manner is of paramount importance. It all boils down to understanding the precise sliver handling requirements at your mills, and acquiring HDPE sliver cans & related accessories accordingly.

With our specially designed and calibrated can calculator, you can get an accurate estimate of the number of cans you need to order. Get started here.

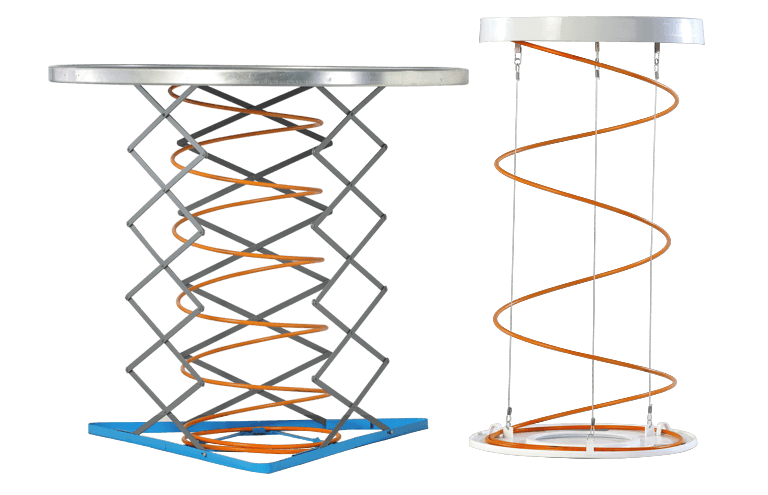

In order to enhance the usability and longevity of spinning cans, they need to have the correct spring load – to ensure complete stability and eliminate tilting risks. Cans with the right spring load ensure fatigue-free performance, optimise sliver handling at all stages of spinning, and improve yarn quality.

Our Spring Load Suggestion calculator has been set up to assist you in this regard.

Select the process (carding/combing) and provide the following details

to calculate the number of spinning cans required at your mill.

| Machine Models | Doublings | Machine Alloted | |

|---|---|---|---|

| Blow Room | lines | ||

| Carding | * | ||

| * | * | ||

| Lap Former | |||

| Comber | |||

| Finisher Draw Frame | |||

| Speed Frame | (Flyer/Spindle per machine) | ||

| Ring Frame |

Select the process (carding/combing) and provide the following details,

to calculate the number of spinning cans required at your mill.

| lines |

| (Flyer/Spindle per machine) |

In order to calculate the correct spring load required in your spinning cans,

kindly fill up the following fields carefully.

Important Links

Important Links

Please accept our website cookies for an enhanced browsing experience. Cookie policy

Drop us an enquiry and do feel free to share your expectations and what you are looking from us.

We will be pleased to get back to you.