Starting from the material selection and up to the application of use, Jumac has an in-depth

team with a vast experience of spinning mills working culture. All the accessories and spares

are easily available and delivered anytime to our customers

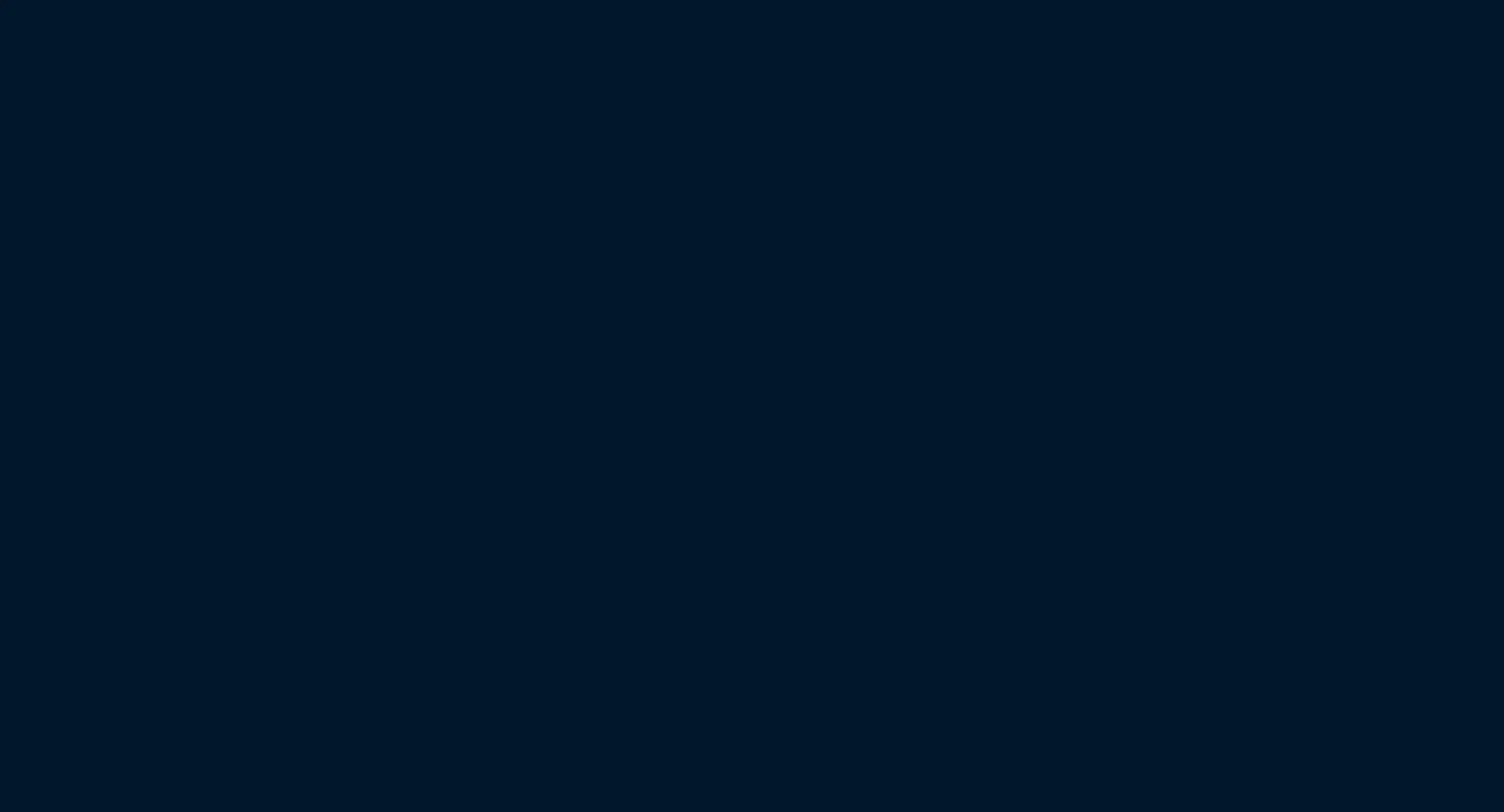

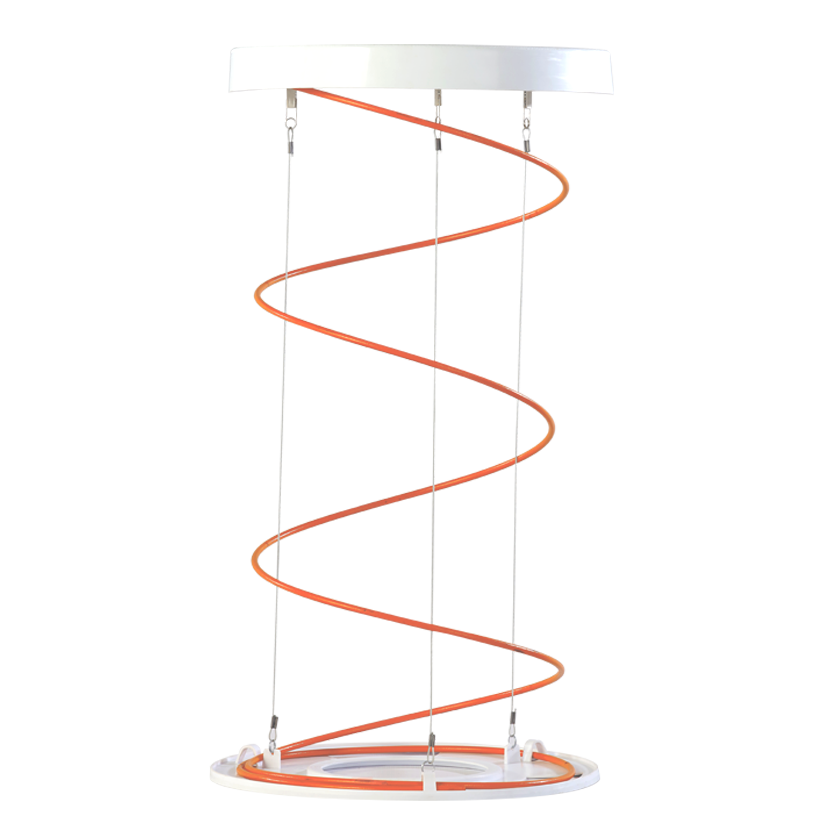

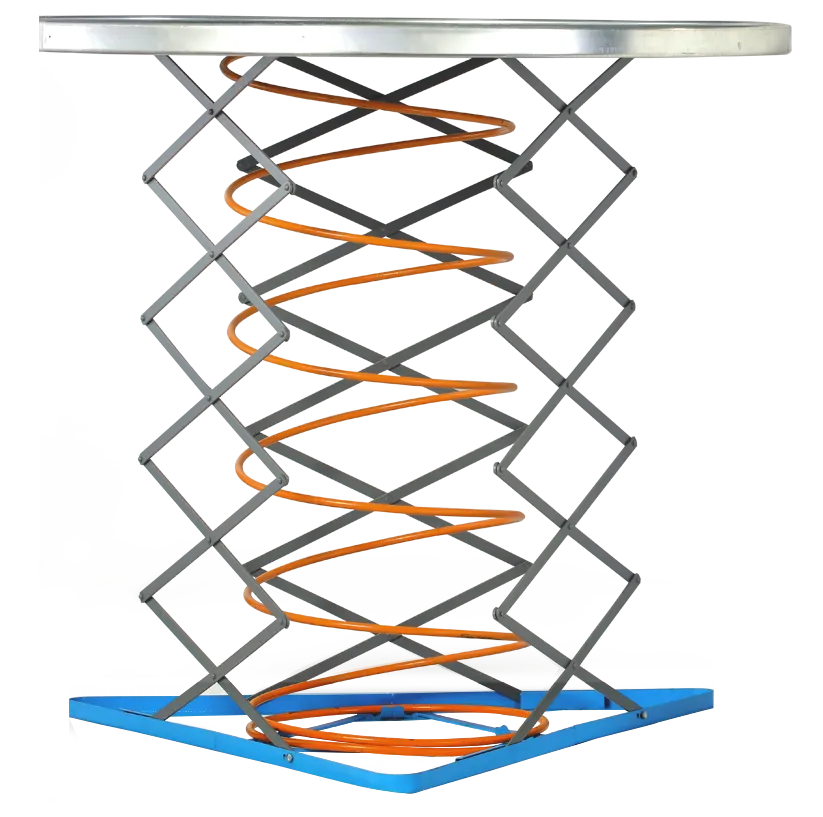

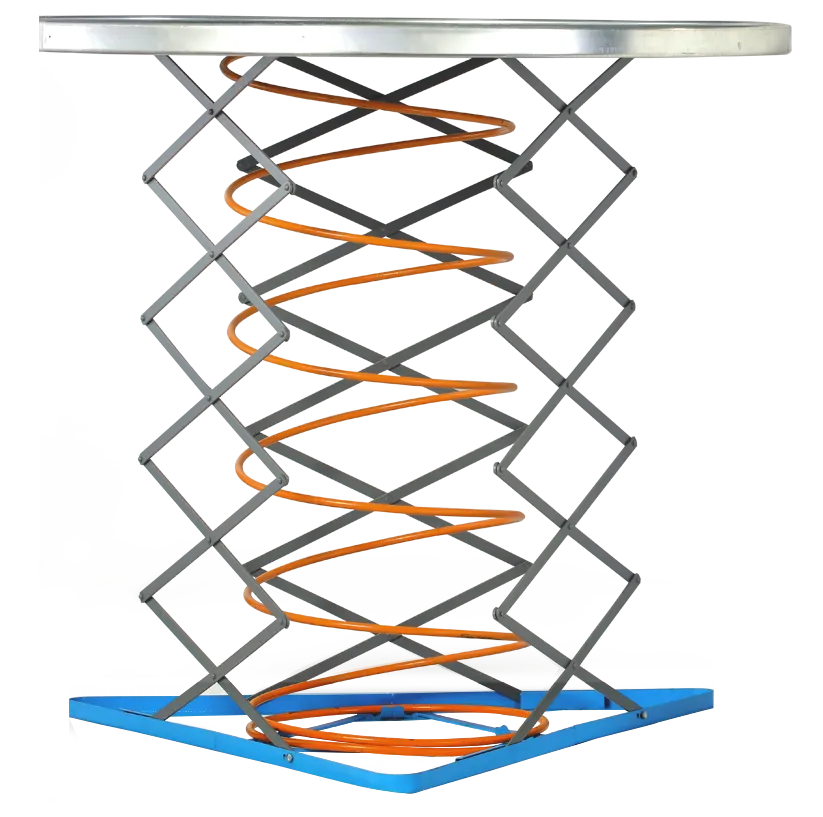

Precisely tempered with heat treatment and carefully calibrated springs is the USP of Jumac springs. The state of the art machinery production line, most advanced R&D testing Lab and trials reports along with vast experience of spring manufacturing gives customers a huge support in selecting the right spring. Springs are available in both types, that is

For cans with diameter from 16″ to 24″

For cans with diameter from 24″ to 48″

For cans with diameter from 16″ to 24″

For cans with diameter from 24″ to 48″

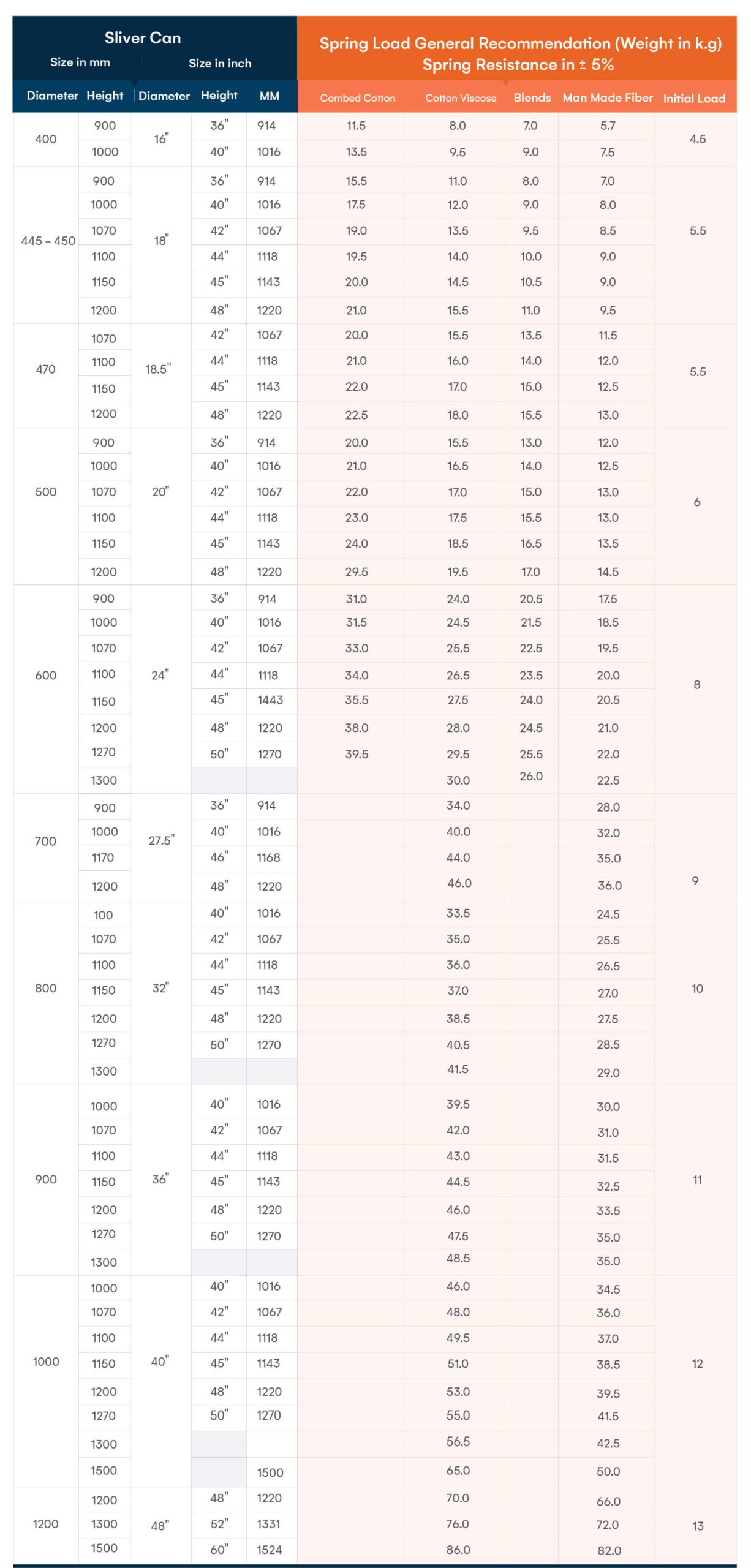

Spring Load Recommendation

Spring Load Recommendation

The Plastic sheets are lightweight, smooth and highly resistant and are used for making sliver cans for enhanced durability & consistent performance. This granule contributes to a world class surface strength. With the inclusion of anti – static agents in the raw materials the appearance of the sheet enhances which gives a dust and dirt free look to the body by neutralizing static charges.

The strong & high-performance zinc-coated, dust and fluff-free caster wheels ensure smooth and trouble free sliver can transportation. Sliver handling on spinning mill floors is made smoother and safer than ever. Jumac casters perform excellently in trolleys of the spinning mills.

Available in 65 mm (2.5″), 80 mm (3″) and 100 mm (4″).

Available in two different sizes (2.5″ and 3″)

Casters with unique ‘Ever Clean’ feature

Available in different diameters, from 78.5 mm to 85 mm

Available in two different sizes (2.5″ and 3″)

Casters with unique ‘Ever Clean’ feature

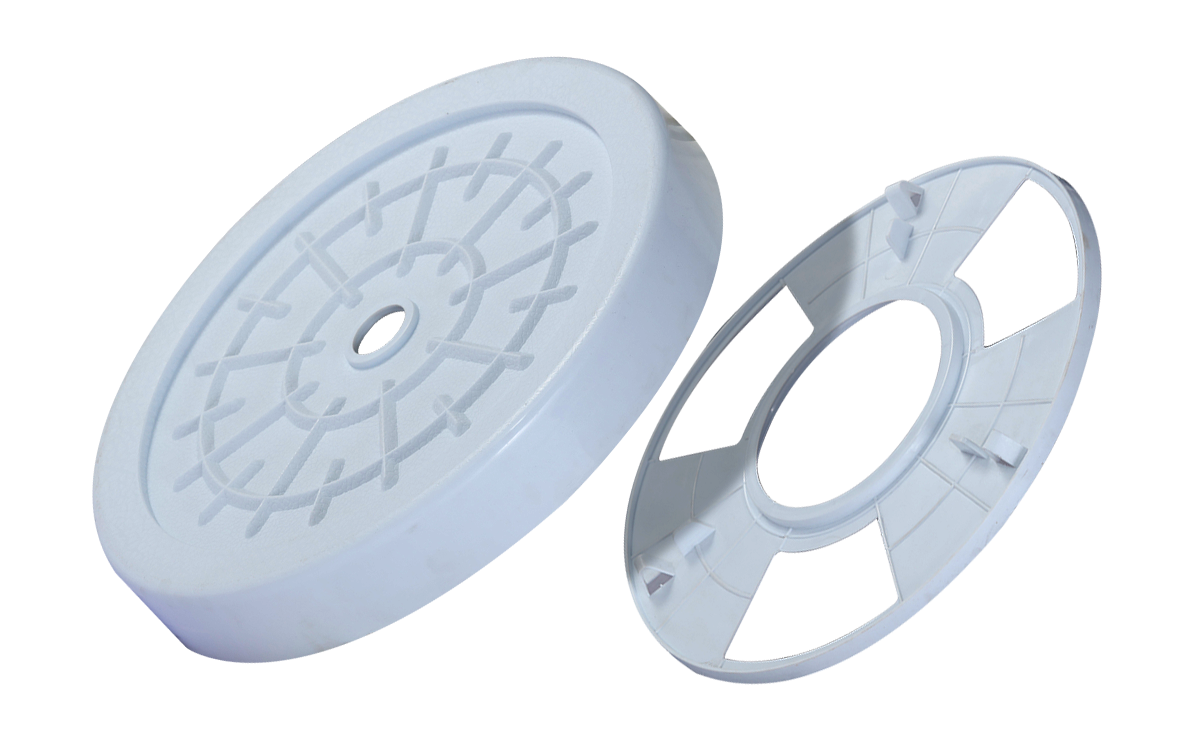

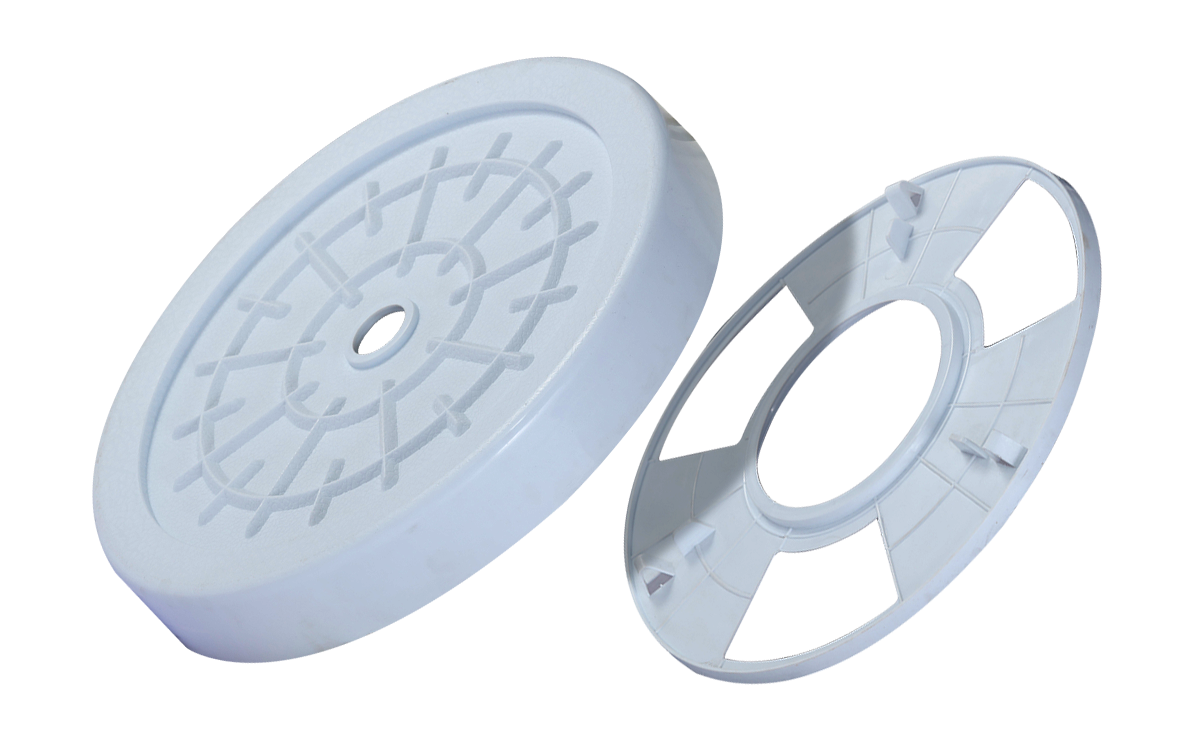

Single plastic moulded top & bottom covers ensure anti-slippage properties giving the extra grip and protection to the sliver.

Our special bottom covers gives balance to the spring and allows it to stand with the support of the stay wires.

Forming the skeleton of the can, we make a careful selection of the raw material to make the same along with the proven robust design to keep the can running for a long time.

Single plastic moulded top & bottom covers ensure anti-slippage properties giving the extra grip and protection to the sliver.

Our special bottom covers gives balance to the spring and allows it to stand with the support of the stay wires.

Forming the skeleton of the can, we make a careful selection of the raw material to make the same along with the proven robust design to keep the can running for a long time.

The strong and embossed galvanised (GP) bottom ring and bottom plate gives the best strong durability and high impact sustainability to the Jumac cans. As this part bears the maximum load of the cans, the selection of the material and its thickness is of immense importance and Jumac provides the best quality material to add more life in the cans. Designed with a heavy-duty press, these accessories have additional ribs & contours for extra reliability.

Drop us an enquiry and do feel free to share your expectations and what you are looking from us.

We will be pleased to get back to you.

Important Links

Important Links

Please accept our website cookies for an enhanced browsing experience. Cookie policy

Drop us an enquiry and do feel free to share your expectations and what you are looking from us.

We will be pleased to get back to you.

Colour Card

Colour Card