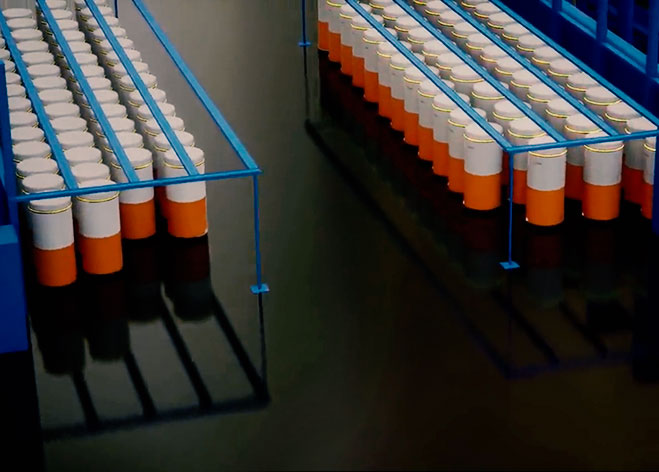

The objective of the JI+ technology is to ensure greater visibility and control over the status of the cans during operations. Discover how this is achieved in this video.

Key Features

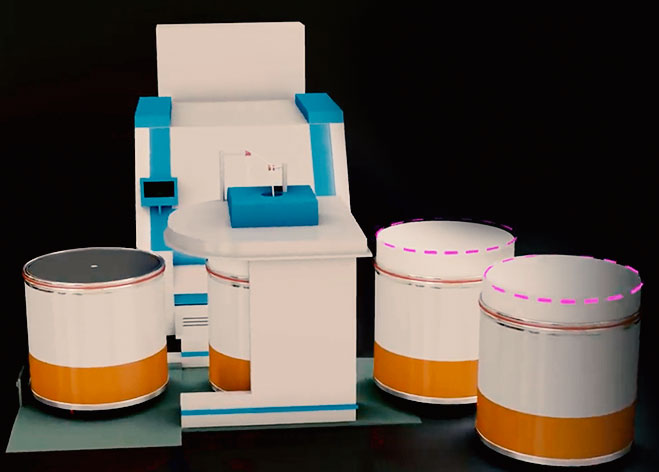

Built-in SENSORS

for detecting sliver status in cans

Data-driven AUTOMATION

to bring information right at the fingertips

End-to-end VISIBILITY

that provide actionable

insights

Centralised CONTROL

to monitor all updated data on devices

Last Mile TRACEABILITY

to detect and resolve operational issues

Full COMPATIBILITY

with SMART CAN

technology

The objective of the JI+ technology is to ensure greater visibility and

control over the status of the cans during operations. Discover how

this is achieved in this video.

Key Features

Built-in SENSORS

for detecting sliver

status in cans

Data-driven AUTOMATION

to bring information right at the fingertips

End-to-end VISIBILITY

that provide actionable

insights

Centralised CONTROL

to monitor all updated data on devices

Last Mile TRACEABILITY

to detect and resolve operational issues

Full COMPATIBILITY

with SMART CAN

technology

Download Ji+ Brochure

Download Ji+ Brochure