The sliver cans manufactured for the spinning industry are used…

Springs- The Heart of Sliver Cans

Springs: the real story/secret of sliver cans

Every piece of yarn becomes cotton only after it achieves the desired level of richness during the manufacturing procedure. From carding to roving and spinning, at each step of yarn processing, there is one indispensable apparatus- the sliver cans. Sliver cans of varied diameter and capacity are used for collection and transportation of cotton yarns throughout the spinning procedure.

The sliver can find their strength from springs embedded within. Sometimes, the sliver can endure high rotational force when the sliver is spun. The sliver that is stored in the cans also exerts a high amount of pressure. Other times, they undergo multiple handling conditions. This demands an internal support system that comes in the form of springs.

Why the spring matters

Each can have a perfect coiled spring that is manufactured from high carbon special steel wire. Heat treatment ensures that the springs have uniform load bearing capacity while being auto-adjustable to sliver pressure. The springs provide unparallel support when it comes to providing stability and maintaining a horizontal position. One of the biggest advantages of the springs is the fact that, they can be calibrated as per height requirements. Thus, irrespective of the load and other surface tensions, the sliver can have smooth uniform doffing and perfect castor fitting.

Perfect springs that make perfect sliver cans

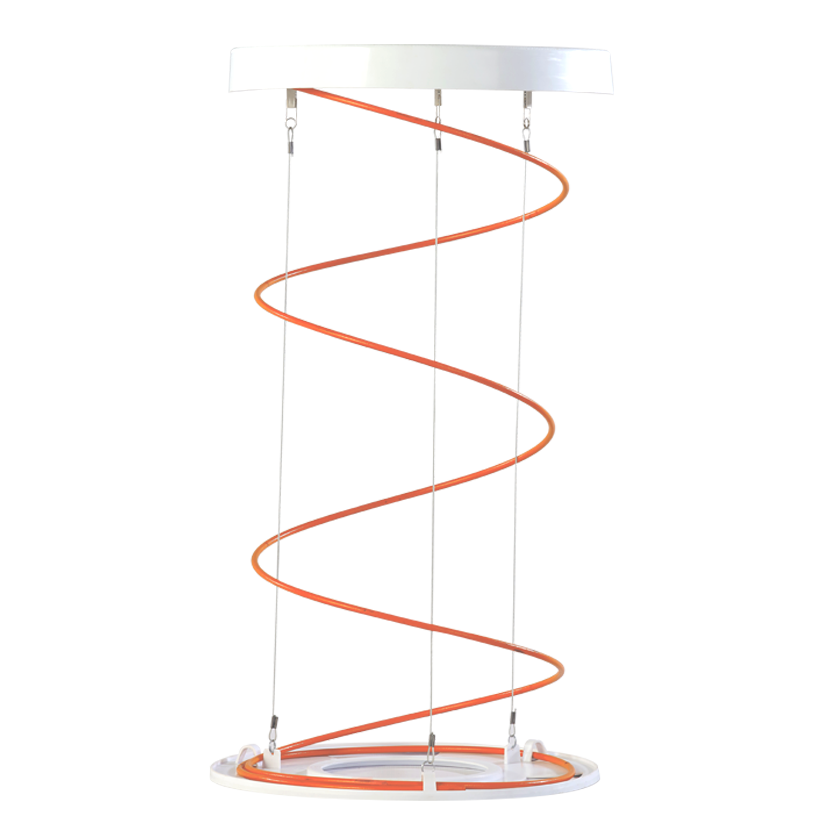

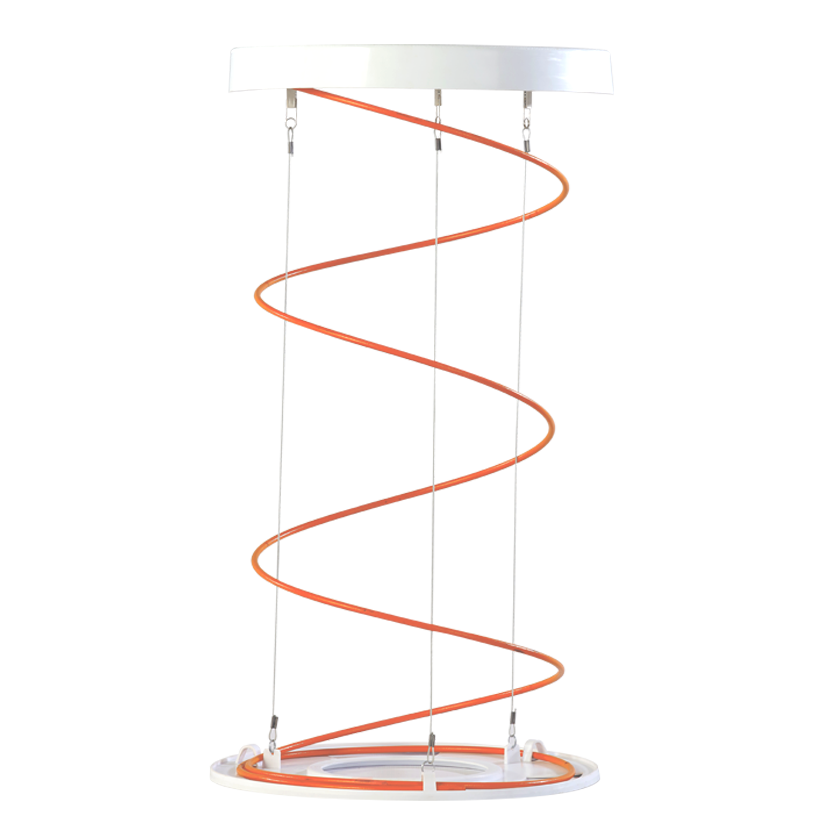

Chiefly, two major types of hardened and tempered precision springs are manufactured by Jumac for spinning cans.

Box spring –

This regular spring is suitable for cans of HDPE sheets of varying thickness. The springs are heat treated, and also possess anti-rust properties. Sliver cans with box type spring are more effective for maintaining desired sliver height during rotor spinning.

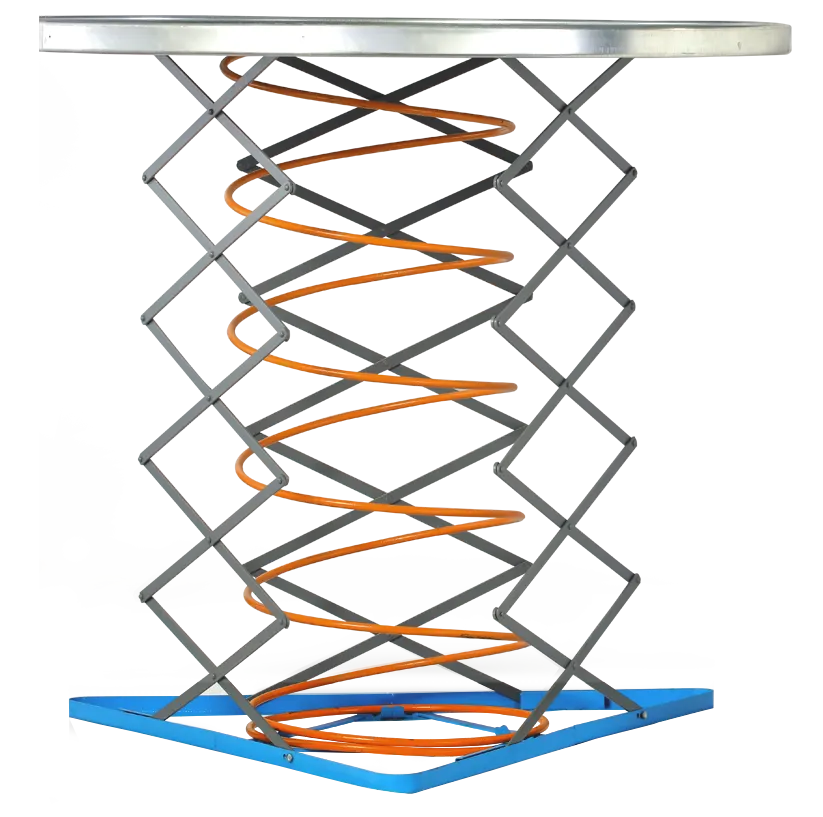

Pantograph spring-

The pantograph springs are high stability springs that ensure that the sliver can maintain balance irrespective of the sliver load. High-quality pantograph springs manufactured by Jumac have electro-welded galvanized (GP) shutters that take up an even crisscrossed shape. This mechanism is particularly supportive of uniform spring movement while upholding a constant sliver height. This hardened and tempered type of spring for sliver cans is known for its capability of retaining original properties of sliver at all stages.

Springs- the heart of sliver cans

Not just providing support and stability, the springs used in sliver can have more roles to play. The springs are attached to the top and bottom parts of the sliver cans to eliminate sliver wastage while adjusting with altering pressures of sliver. Best quality springs are lightweight, rigid and are anti-corrosive. For high stability of slivers, often the pantograph spring arrangements are customized according to the requirement of individual spinning houses. Thus, without springs, sliver can for jute or textile industry would be unable to produce desired yarn quality.

Passionate about transforming the industrial sector of textile and spinning industry with innovative solutions. Director at Jumac Manufacturing, leading spinning cans and accessories manufacturer and exporter from Kolkata, India.