The world might be showing early signs of recovery from…

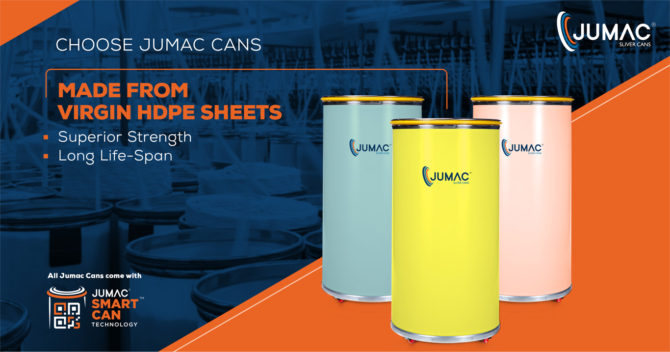

Why choose Virgin Quality HDPE for Spinning Cans Body Sheets?

Spinning Can bodies, made from HDPE (High-Density Poly-ethylene) sheets are in great demand in spinning mills as they offer strength, durability and longer life to the Cans. These sheets have an inherent quality of holding the shape of the Cans firmly which adds accuracy in the carding process ensures better yarn quality.

Why is HDPE Sheet used in Can Body?

HDPE provides a structurally stronger surface to the Cans than any other composite material. Also, HDPE sheets do not emit any chemical compounds in the air at normal temperatures thereby has less health hazard for workers. It also ensures that the body remains intact and does not require frequent re-painting or touch-up. HDPE sheets also are:

- Extremely Lightweight

- Easily Malleable (foldable and transformable into any shape)

- High Chemical and Impact Resistant

- Resistant to Extreme Weather

- Durable and Long-Lasting

- 100% Recyclable and Sustainable

What are HDPE Sheets made from?

HDPE Sheets used for Spinning Can bodies are made from HDPE Resins. They have good barrier properties and stiffness, and are well suited to hold on the shape of the can firmly. As HDPE Sheets are mostly resistant to chemicals, they are one of the primary choices in manufacturing and industrial applications. There are two types of HDPE resins available in the market (a) Virgin Quality resins and (b) Recycled Quality resins.

Virgin Vs Recycled HDPE Resins

When plastic is modified in processing, it undergoes heat and pressure. The application of heat and pressure puts strain on the molecular structure of the plastic, and the more number of times this occurs, the molecular structure keeps on becoming weaker.

Virgin resins when put through the correct design and process, are typically more durable on the molecular level than recycled resins. Pallets made from recycled resins are typically more brittle.

Customers always fall into a common trap of preferring Body Sheets made from Recycled Resin pellets as a cheap option, which however proves to be more expensive in the long run.

Body Sheets made from Virgin Quality HDPE resins, make a perfect choice.

Virgin HDPE is non-toxic & non-staining, and offers excellent impact resistance, light weight, low moisture absorption, and a high tensile strength. The advantages possessed by this polymer make it more preferable over composite or recycled materials. Lightweight, ease of manufacturing, strength and toughness are few of its qualities which make it the perfect choice for a longer life of the Cans.

Working closely with global clients, Jumac understands the importance of every small essential that makes sliver cans all the more effective. It uses body sheets manufactured from Virgin HDPE resins.

Thinking of ordering Sliver Cans? Contact Us

Passionate about transforming the industrial sector of textile and spinning industry with innovative solutions. Director at Jumac Manufacturing, leading spinning cans and accessories manufacturer and exporter from Kolkata, India.