Desde a seleção do material até a aplicação do uso, a Jumac conta com uma equipe de vasta e aprofundada experiência na cultura de trabalho das fiações. Todos os acessórios e peças sobressalentes estão facilmente disponíveis e entregues a qualquer momento aos nossos clientes.

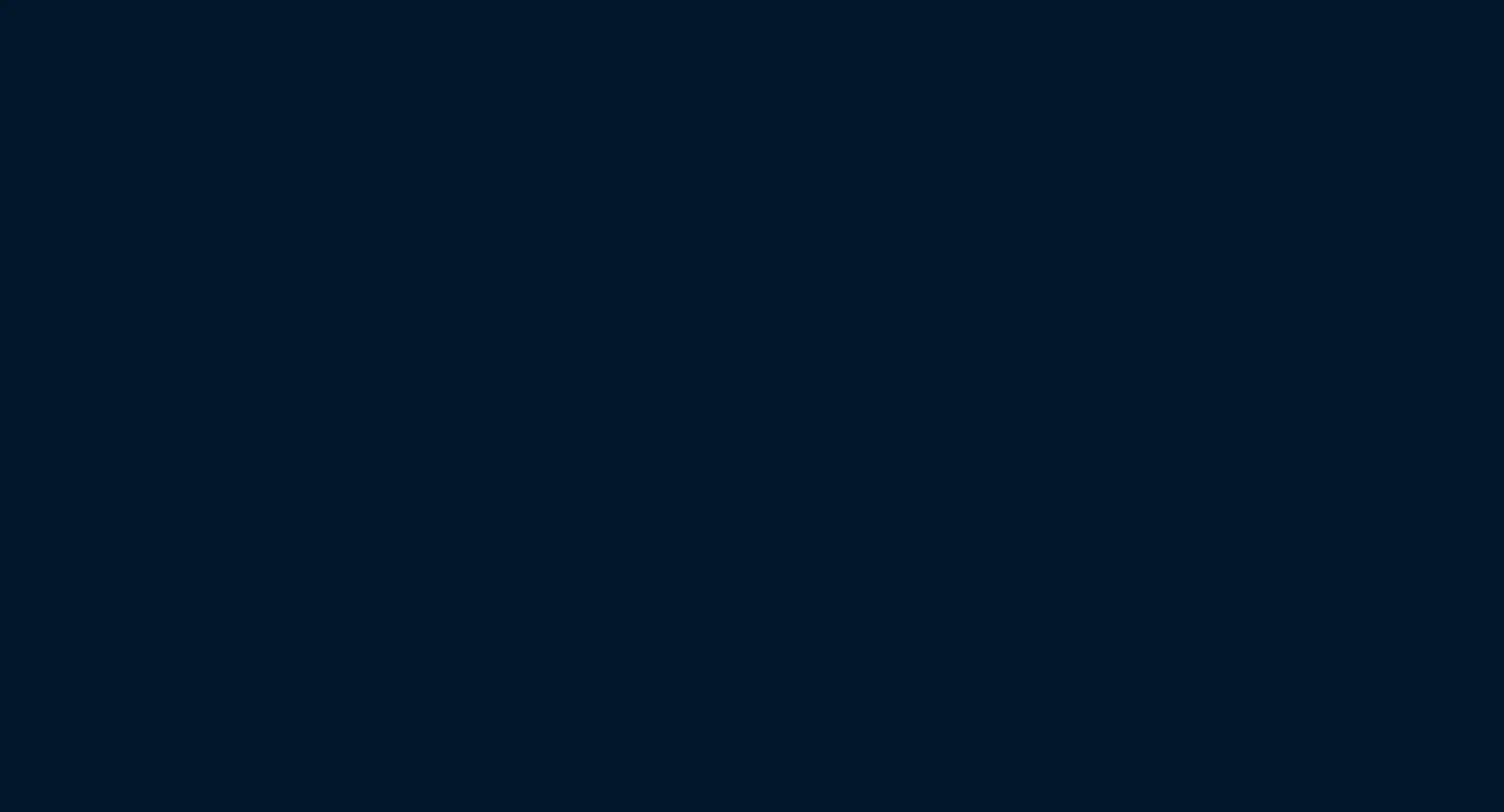

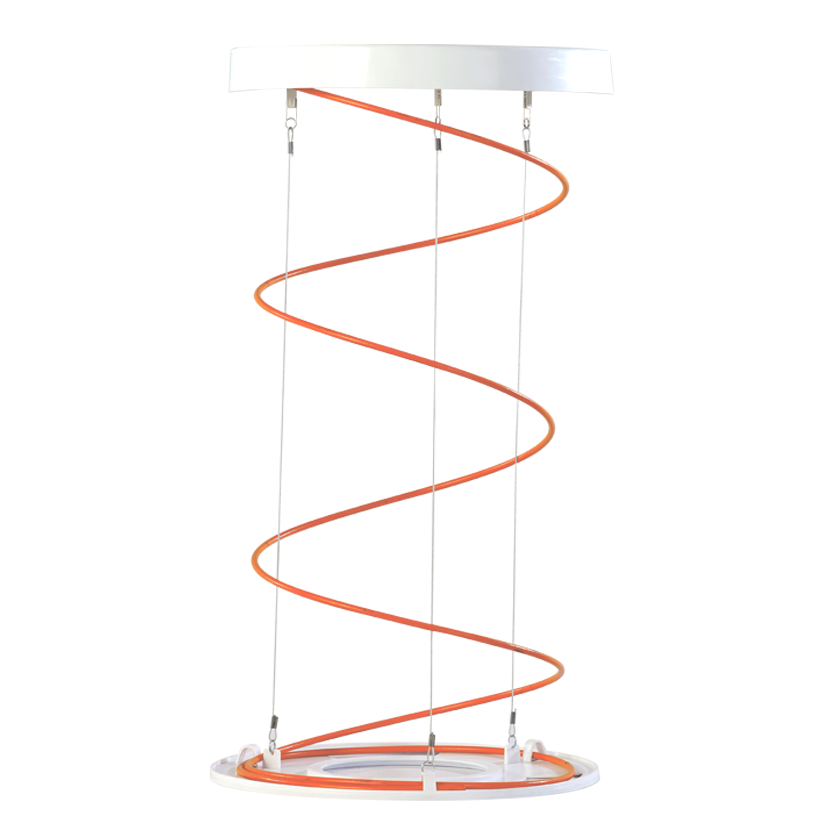

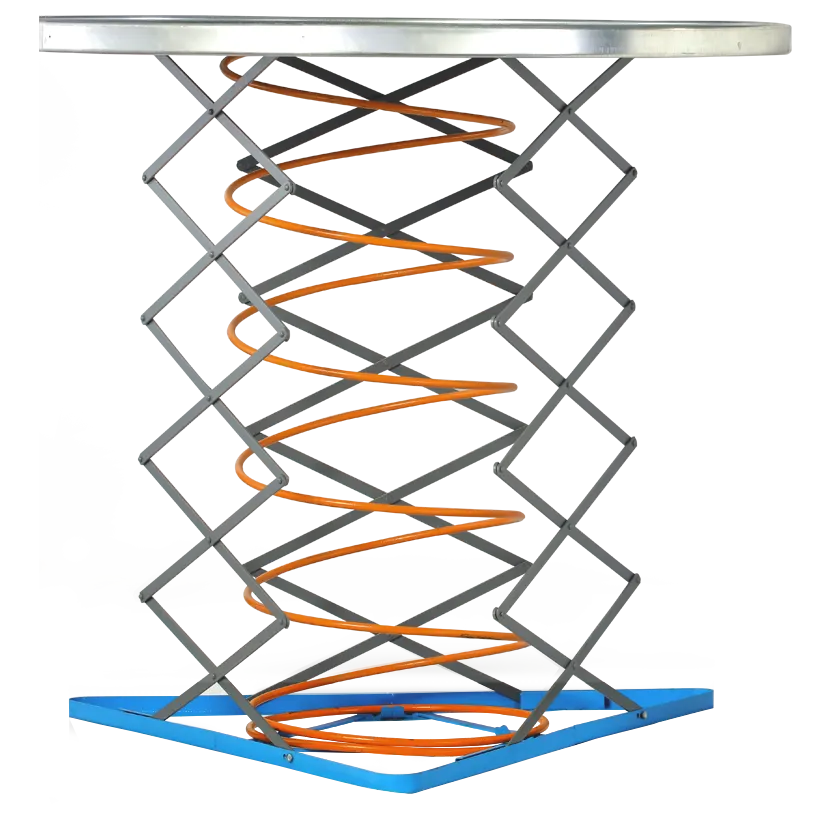

Precisamente temperada com tratamento térmico e molas cuidadosamente calibradas na unidade de produção das molas Jumac. A linha de produção de máquinas de última geração junto do mais avançado laboratório de testes e ensaios R&D com vasta experiência na fabricação de molas oferecem grande suporte aos clientes na seleção da mola correta. As molas estão disponíveis em ambos os tipos, sendo elas

Para latas com diâmetro de 16″ a 24″

Para latas com diâmetro de 16″ a 24″

Para latas com diâmetro de 16″ a 24″

Para latas com diâmetro de 16″ a 24″

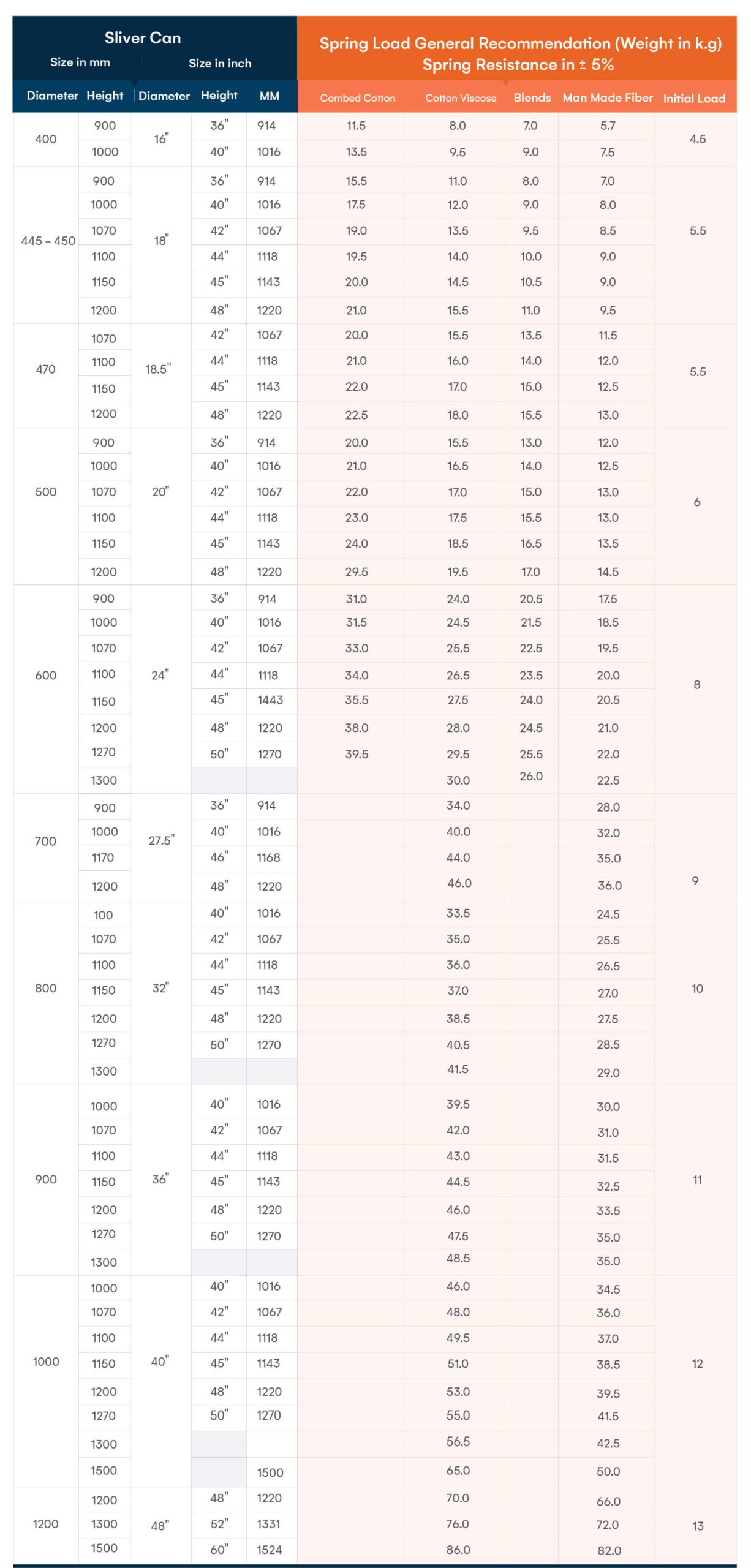

Recomendação de carga de mola

Recomendação de carga de mola

O corpo de plástico é feito de folhas HDPE (Polietileno de alta densidade) são leves, lisas e altamente resistentes e são usadas para fazer latas com maior durabilidade e desempenho consistente. O material de HDPE contribui para uma resistência superficial de classe mundial. Com a inclusão de agentes antiestáticos nas matérias-primas, a aparência da folha melhora, o que dá uma aparência livre de poeira e sujeira ao corpo, neutralizando as cargas estáticas.

Os rodízios são revestidos de zinco, fortes e de alto desempenho, livres de poeira e fibras, garantem um transporte suave e sem problemas para latas de fita. O manuseio de fitas em pisos de fiações é o mais suave e seguro do que nunca. Os rodízios Jumac têm um desempenho excelente nos carrinhos das fiações.

Disponível em 65 mm (2,5″), 80 mm (3″) e 100 mm (4″).

Disponível em dois tamanhos diferentes (2,5″ e 3″)

Disponível em dois tamanhos diferentes (2,5″ e 3″)

Disponível em dois tamanhos diferentes (2,5″ e 3″)

Disponível em dois tamanhos diferentes (2,5″ e 3″)

Disponível em dois tamanhos diferentes (2,5″ e 3″)

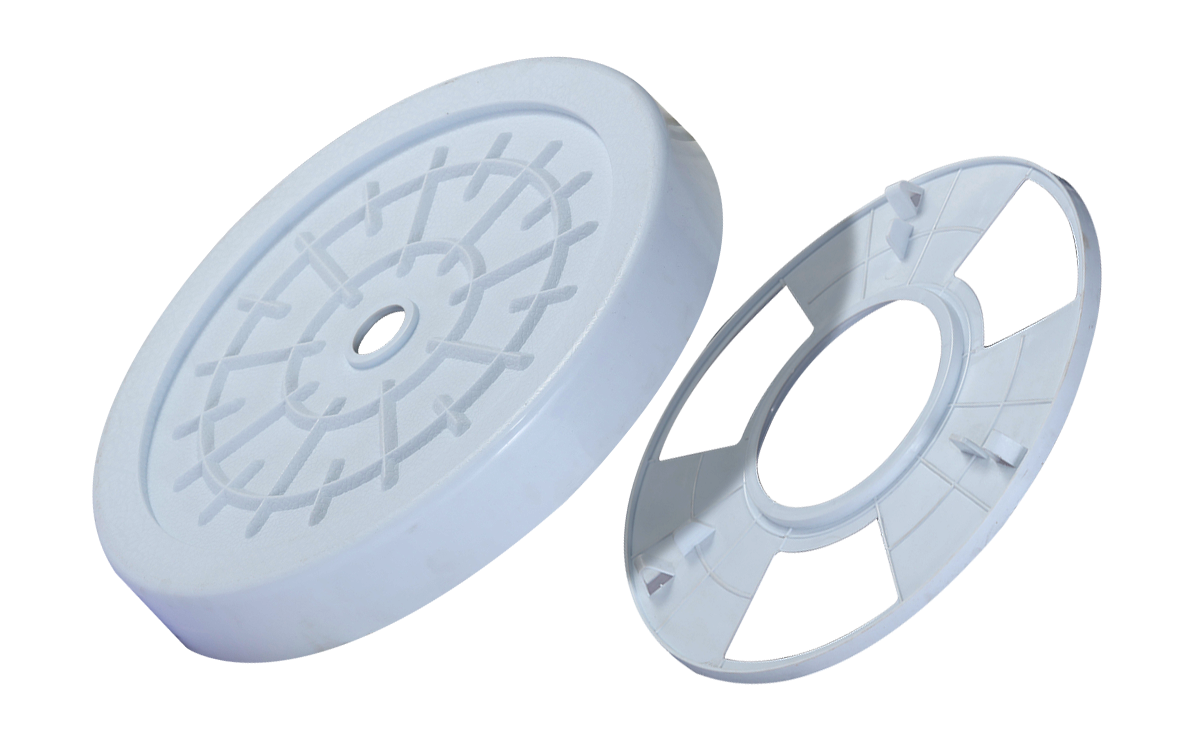

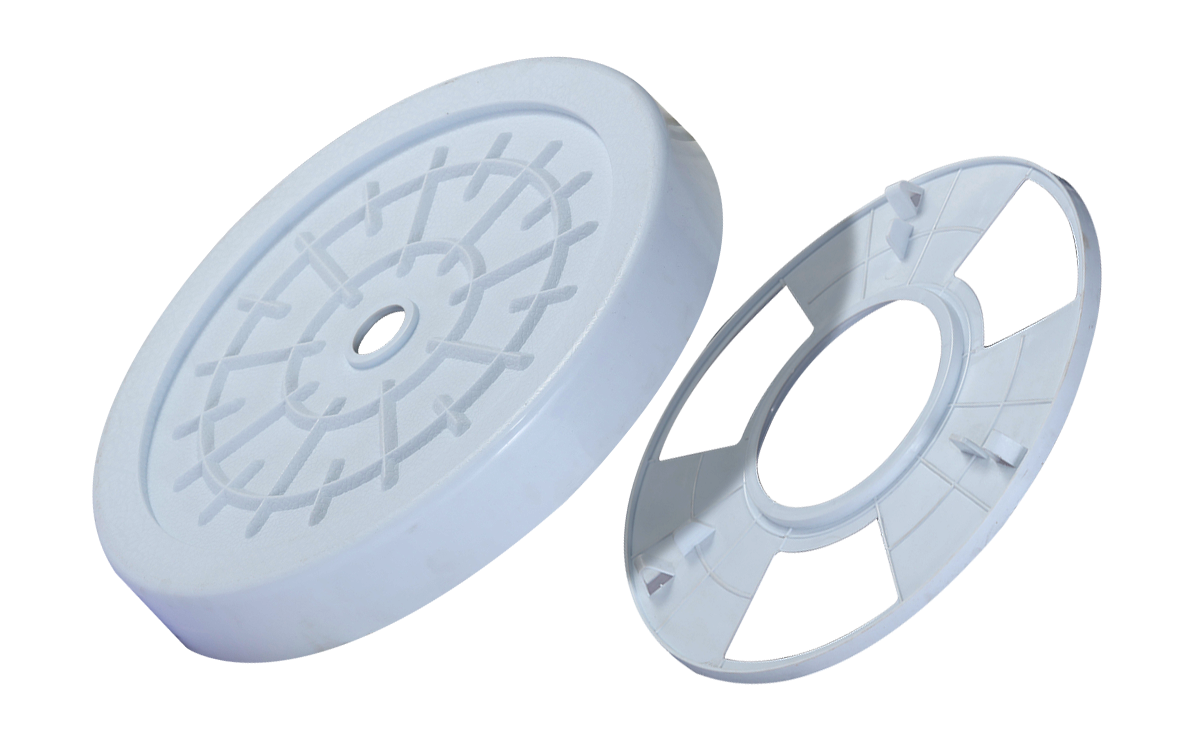

As tampas superior e inferior moldadas em plástico único garantem propriedades antiderrapantes, dando a aderência extra e proteção para a fita.

Nossas tampas inferiores especiais dão equilíbrio à mola e permitem que ela estabilize com os fios de aço.

Na formação da estrutura da lata é elaborada uma seleção cuidadosa da matéria-prima, juntamente com o design robusto comprovado para manter a lata funcionando por um longo tempo.

As tampas superior e inferior moldadas em plástico único garantem propriedades antiderrapantes, dando a aderência extra e proteção para a fita.

Nossas tampas inferiores especiais dão equilíbrio à mola e permitem que ela estabilize com os fios de aço.

Na formação da estrutura da lata é elaborada uma seleção cuidadosa da matéria-prima, juntamente com o design robusto comprovado para manter a lata funcionando por um longo tempo.

The strong and embossed galvanised (GP) bottom ring and bottom plate gives the best strong durability and high impact sustainability to the Jumac cans. As this part bears the maximum load of the cans, the selection of the material and its thickness is of immense importance and Jumac provides the best quality material to add more life in the cans. Designed with a heavy-duty press, these accessories have additional ribs & contours for extra reliability.

Deixe-nos uma pergunta e sinta-se à vontade para compartilhar suas expectativas e o que você está buscando. Teremos o maior prazer em entrar em contato com você.

Important Links

Important Links

Please accept our website cookies for an enhanced browsing experience. Cookie policy

Drop us an enquiry and do feel free to share your expectations and what you are looking from us.

We will be pleased to get back to you.

Cartão de Cores

Cartão de Cores