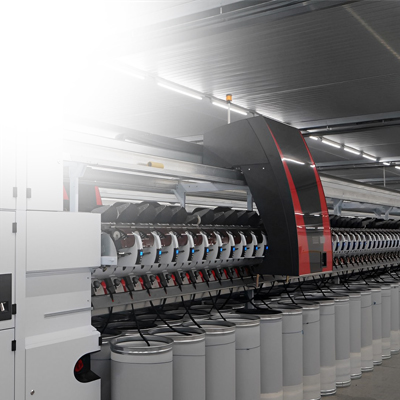

Use Of Cans In Open-End Spinning

The open-end spinning cans from Jumac that are used to make the process of feeding the sliver from the drawframe through the rotor spinning machine, come with complete quality assurance. They play a key role in maximising the overall rotor spinning productivity and eliminate the risks associated with rotor stripping.