The highest of standards. The finest of materials. The best of technology. Spinning cans from Jumac redefine quality, compatibility and value in yarn-making processes. These cans deliver reliability, assurance and performance in every phase of spinning - right from blow room, carding, combing, draw frame to roving. Important quality parameters like U% and CVm are totally retained by the Jumac Cans thus yarns produced are of premium quality.

Delicate yarn needs to be handled with expert care. Spinning cans from Jumac eliminate sliver breakage and sliver deflections, to ensure sliver parameters are retained to make perfect doffs possible.

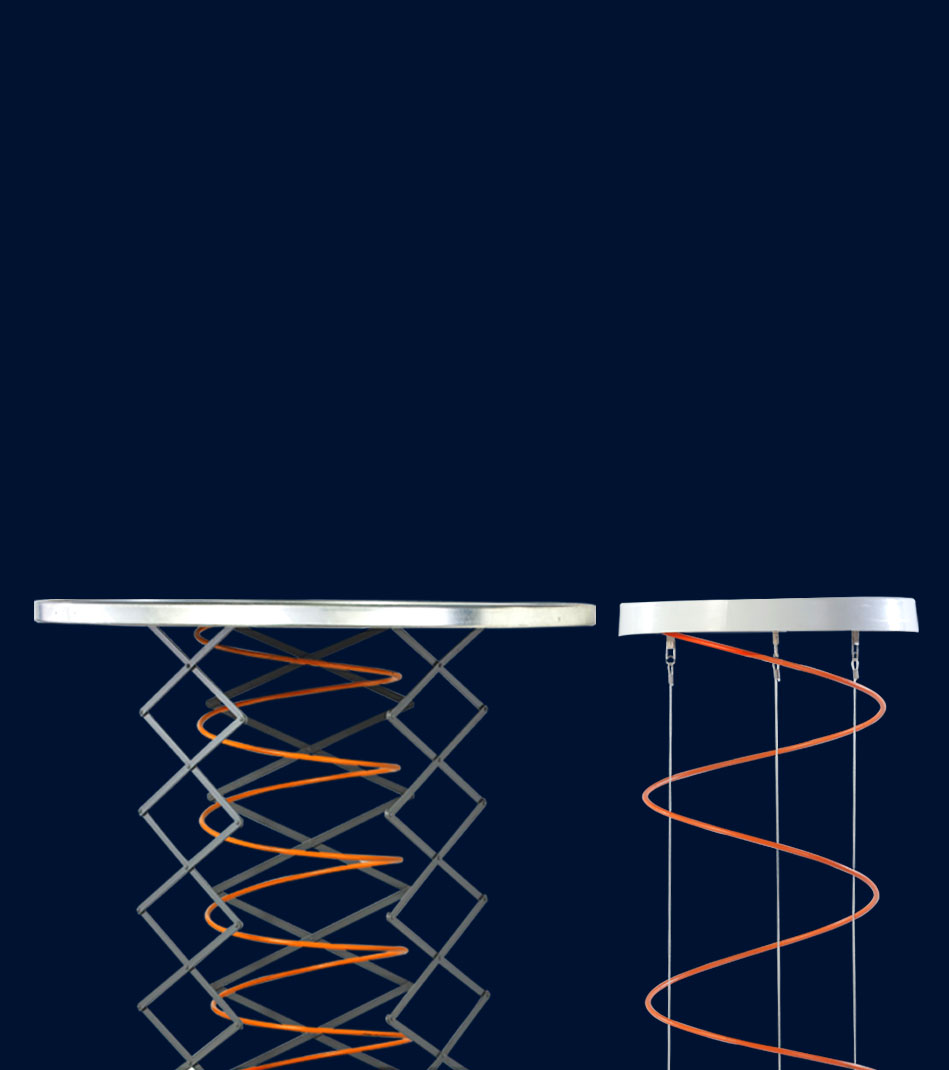

Our spinning cans are fitted with anti-static plastic sheets, super mobile casters, high-stability springs and other robust spares & accessories. Manufactured in-house and with the very best components, our products are of unmatched excellence and help in delivering the finest-quality output.

The sliver cans are fitted with hardened & tempered box and pantograph springs that ensure enhanced stability during high-speed spinning processes, ensuring no chances of sliver deflections.

Ergonomically designed caster wheels, made of premium-grade CR Sheets, and with ribs & contours, to ensure easy cleaning & maintenance and superior longevity.

Redefine carding

with MORE sliver

capacity & yield

With perfect doffs, smooth sliver handling, and zero

imperfection assurance, Jumac spinning cans are the

preferred choice of leading spinning machinery OEMs.

Drop us an enquiry and do feel free to share your expectations and what you are looking from us.

We will be pleased to get back to you.